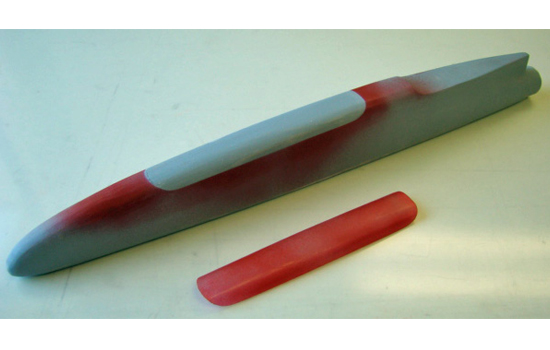

We will start by making a mold for the fuselage hatch, this way we will make a pattern for the hatch and use the hatch pattern to make the fuselage pattern fit the hatch perfectly. Applying mold release to the pattern, it is important to apply both Partall mold release wax and Coverall liquid mold release. Waxing is repeated; a number of times depends upon the surface. If the surface has any potential for porosity, multiple coats are needed. These layers of wax will fill the tiny surface imperfections. If you have any doubt, add more layers of wax. If they are not filled completely, the epoxy will lock into these imperfections. Liquid Coverall mold release is then applied over the wax.

Coverall can be applied with a good quality paint brush, water can be used to clean the paint brush after each coat. Apply a thin even coat being careful to eliminate any excess liquid or runs. Let this coat dry and apply a second coat to assure complete uniform coverage.

Dust and dirt can be trapped by the mold release as it dries and becomes a part of the mold surface. If you have any defects in your mold release remove the layer with water and a paper towel and reapply the Coverall mold release. The surface you see in the mold release will be the surface finish you will see in the mold and the parts. After you mold the part the mold release must be removed from the mold and the part with water and a paper towel and reapplied before the next molding operation.

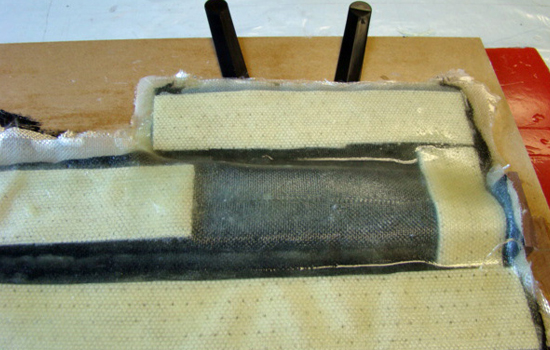

Now you are ready to start applying the layers of epoxy and fiberglass cloth. Use the following West System Epoxy products:

105 Resin is a low viscosity resin that easily wets out the cloth and allows for minimal air bubbles between the cloth layers.

205 Fast Hardener allows sufficient time to wet out each layer then gels up quickly so the mold building process can be completed in a few hours.

406 Colloidal Silica is used to thicken the epoxy system to aid in applying epoxy to vertical surfaces, filling corners and details in the mold.

423 Graphite Powder is used to give the tooling coat layer of the mold a black color and a harder, more durable surface.